Getting machines for your small workshop does not have to cost the earth. You will find various machines at affordable prices if you shop around or purchase pre-owned equipment.

Before you do so, you need to consider which machinery will benefit your workshop operations the most. To help you get started, here are five affordable machines that most every small workshop can benefit from having.

1. Robotic Welder

If you are looking to increase the accuracy of welding processes and reduce the time it takes to weld, you should consider getting a robotic welder for your workshop.

Robotic welding is basically a highly advanced form of automated welding. You only have to supervise the process. The welder does the rest. Furthermore, using welding robots increases safety.

Robotic welding machines are available in various sizes. You can also get great deals in the second-hand market for robotic welders. For instance, you could get a pre-owned one for a fantastic price from leading brands like Lincoln and Miller PerformArc.

To attain a higher degree of precision and quality with your welding, you cannot go wrong with a robotic welding machine.

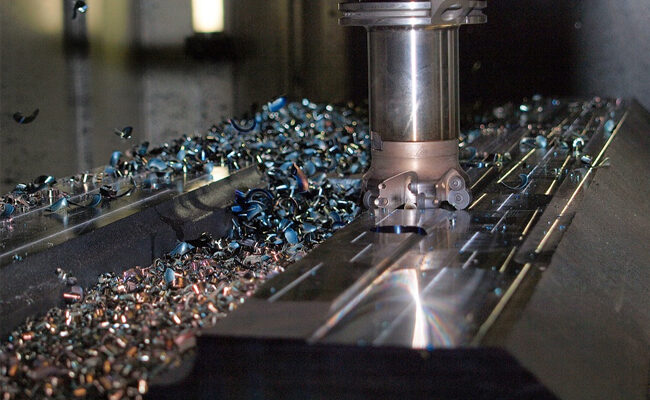

2. Milling Machine

A milling machine should be a vital part of any small workshop.

Again, you can find different types of milling machines from various brands, including used milling machines, so you should be able to afford one for your workshop.

The machines can be used for a wide variety of purposes, such as creating external and internal threads, machining contoured and flat surfaces, and cutting slots and gears.

Milling machines can be used with numerous materials too. So, whether you are using metal, wood, or plastic in your milling processes, a milling machine is a must for your workshop.

3. Lathe Machine

Lathe machines are ideal for a plethora of operations, including cutting, drilling, knurling, facing and turning. They work by rotating the workpiece around the cutting tool, which is stationary.

While mostly used for shaping metal or wood, there are specialized lathe machines for other materials. Depending on your specific needs, you could even consider buying a CNC lathe, which uses computer numerical control to precisely and accurately automate processes.

You will find pre-owned lathe machines available, so they are affordable for small workshops. Indeed, you can also find new lathes at reasonable prices.

4. Boring Machine

Boring machines are anything but boring.

They produce precise and smooth holes in a workpiece by enlarging an existing hole.

Depending on the type of boring machine, that could be accomplished by a cutting tip of steel, cemented carbide, or diamond. The more affordable boring machines use small grinding wheels, and they perform just as well.

The single-point tool is gripped in the boring head and attached to a spindle that is rotating. It then moves circularly against the existing hole to accomplish enlargement.

If boring is a part of your everyday small workshop operation, you need an exciting boring machine.

5. Surface Grinding Machine

For finishing processes, a surface grinding machine is one of the best pieces of equipment you can have.

It uses a grinding wheel to remove material from the surface of a workpiece. It can also be used for abrasive machining processes in which abrasives are placed on the workpiece’s surface. That enables a greater degree of accuracy.

Surface grinding machines are widely used because they have excellent material removal capacity, typically ranging from 0.25 mm to 0.5 mm.

If you want to ensure your workpieces are finished with quality and high precision, get a surface grinding machine for your small workshop. You will find ones available from various brands, so shop around to find an affordable one.

Leave a Reply