The use of glass fibre reinforced concrete GFRC doesn’t have a very long history. It was introduced in the United Kingdom back in the 1970s. In the past few decades, it has gained immense popularity when it comes to building materials. It is used almost everywhere in the world due to its remarkable uses and benefits. GFRC is a very significant type of fibre-reinforced concrete. The enhanced use of GFRC has opened a gateway for builders to go beyond boundaries when it comes to construction. Here are some of the benefits and applications of glass fibre reinforced concrete;

What is Glass Fibre Reinforced Concrete (GFRC)?

It is a composition of fine aggregate, Portland cement, acrylic copolymer, water, additives, and glass fibre reinforcement. It is Cementitious material made of these primary components. Due to the exceptional materials, the product has more tensile strength than ordinary concrete. The best part about GFRC is that it’s lightweight with the same strength as normal concrete. Moreover, it can be made into any texture, shape, or color to increase creativity. Premix and Spray-Up are the two processes that are utilized to fabricate GFRC. Several production techniques are utilized in these processes.

Benefits of GFRC

Here are the benefits of Glass Fibre Reinforced Concrete (GFRC);

Less weight and more strength

One of the most prominent benefits of GFRC is that it comes with low weight and high strength, giving it a clear edge against many other types of concrete. If the demands on the foundations are minimized, and the use of GRC is made evident, it is said to decrease the self-weight of structures. No matter if it’s a multiple-floor building or seismic loading, GRC cladding will help a lot. It’s an amazing fact that it is 75% lighter than traditional concrete if similar pieces are cast. The strength-to-weight ratio is also exceptional.

Diversity in shapes

There are several shapes to mold glass fibre reinforced concrete, may it be 3-D objects, intricate grilles, or even panels with a double curvature too. The versatility in shapes increases the efficiency of the overall projects. No matter if it’s about the detailing of modern or historic buildings, this is easily used to produce remarkable features. It is not hard to mold it into any complex shape without compromising on its toughness.

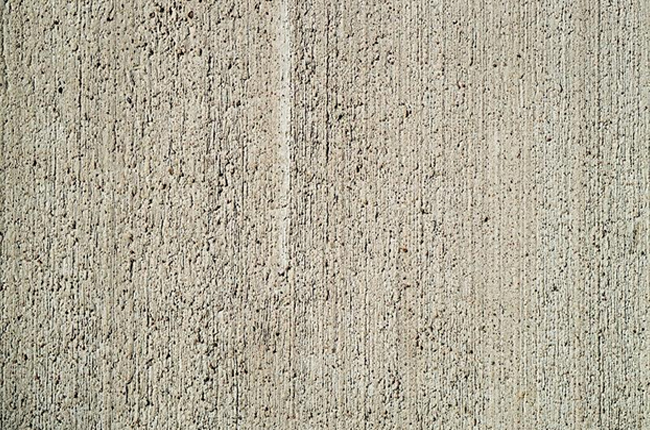

Appearance

There’s no denying the fact that there is a variety when it comes to surface finishes, and GFRC tends to give you a lot of it. As several new appearances are hitting the market every year, it tends to meet the requirements with decent efficiency. If you are planning to match the texture with an existing building, that option is available too. The surface finishes are highly attractive and worth paying for. Not only the textures but there are brightly colored surfaces available. No matter what the shape or texture, self-cleaning is also achievable. You can choose the most-suitable glass fiber reinforced concrete for your project without much hustle.

Longevity

Like traditional reinforced concrete, it is not attacked by corrosion. It has the capability to outcast strong entities such as cast stone and precast concrete. Low alkaline cement has been used to increase the longevity of GFRC. The resistance is high when it comes to dealing with extreme conditions such as fire, freeze, and even thaw. The high level of resistance is one of the major reasons it can last much longer without losing its shape and toughness. The materials used in the making of GFRC have a pivotal role to play in its high durability, primarily low alkaline cement.

Protecting the environment

In this 21st century, there are several environmental challenges to face. Harmful human practices have caused immense damage to the environment. As GFRC are low in weight, it is easier to transport them without emitting excessive amounts of CO2 into the environment. May it be the production cycle or the material, there are no pollutants thrown out into the environment. Moreover, it is recyclable in many applications as well as concrete. The additional cost to save the environment is minimal when it comes to the use of glass fibre reinforced concrete.

Applications

There’s surely variety in the use of glass fibre reinforced concrete (GFRC). Due to its remarkable benefits, it is used in multiple sectors. Buildings of almost every category have been constructed with the use of GFRC. Not only that but many unsophisticated items that cater to the daily demands are made by this product. To tackle structural complexities, GFRC helps architects a lot. Durability, toughness, and diverse appearances are the reasons that many architects prefer using them. Better environment performance is the need of the hour and GFRC gives you that too.

One of the most well-known uses of GFRC is in building renovation works. As the latest textures and distinctive colors can be attained using it. It is also used in the water and drainage industry due to its high durability. Apart from these applications, it is used in bridge and tunnel lining panels as well as architectural cladding.

As mentioned earlier, it is not a very old product. It is a result of remarkable experimentation. However, there is still research going on to discover the large scope of GFRC and to open more gateways to efficient construction. The freedom of shape is one of the major factors that is getting great hype globally and it’s gaining more trust too. Structural complexities efficiently deal with GFRC even if it is used for small scale household products or large buildings. The shipping and installation cost is also less due to its lightweight. Such environment-friendly materials are much-needed in these times. If you are planning to use GFRC for any big or small project, choose a suitable texture and color for your project.

Leave a Reply