When your machine malfunctions, you need to find out which part is causing the problem. After that, you need to figure out what to do. You might be forced to replace that part with the issue or consider buying another machine. However, before you decide, it’d be best to get an expert’s opinion to avoid making the wrong decisions.

An example of a machine part that can be replaced when it has a problem is a carbon brush. This article defines what a carbon brush is and guides you on how to check if carbon brushes need replacement. Continue reading to learn more.

What Is A Carbon Brush?

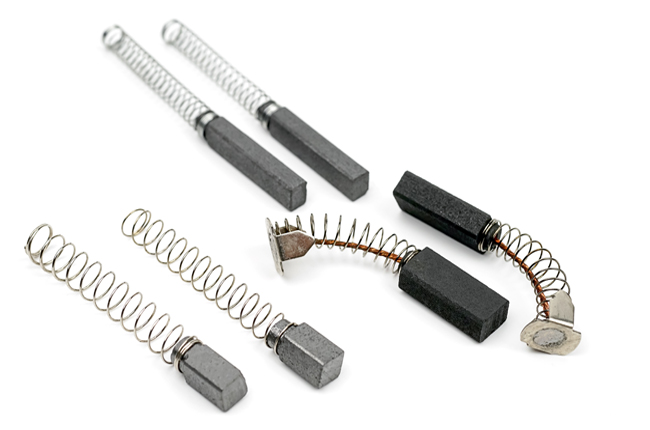

A carbon brush is an electrical contact found in electric motors that’s used to conduct current between rotating and stationary parts of a motor. You can find carbon brushes in washing machines, fans, sewing machines, vacuum cleaners, hair dryers, juicer mixers, and many more.

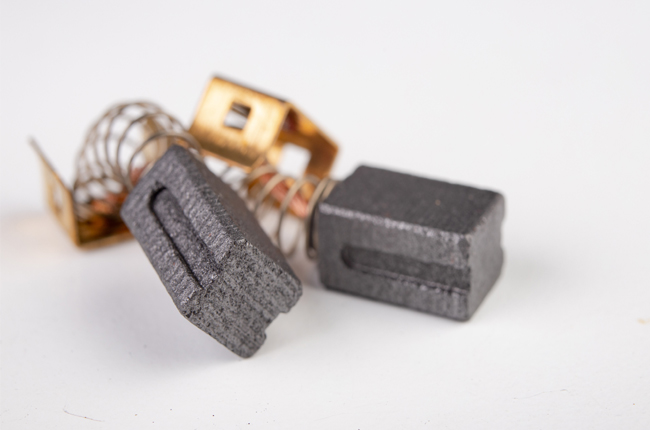

Carbon Brushes For Power Tools

TDO Carbon stock a range of carbon brushes for power tools, from top brands like Bosch and Evolution. Consider checking them out for some of the best carbon brushes.

Carbon brushes wear out due to the high energy they transmit. When the carbon brushes wear out, they can be replaced. However, sometimes, you may confuse malfunctioning carbon brushes for the entire machine being broken. That’s why you have to know how to check if the carbon brushes need replacement.

“Carbon Brushes for a Circular Saw”

Checking For Carbon Brush Replacement

If you’ve been wondering how to diagnose worn our carbon brushes, consider following the guide below:

Test Whether Your Machine Is Performing Well

All machines that are in good condition are expected to perform well. This means if your machine has poor or inefficient performance, then it needs to be checked. Although poor performance is a general sign, this could mean that you need to replace the carbon brush.

Poor performance by a carbon brush could be caused by dirt accumulation. When dirt accumulates around the carbon brush, it prevents the connection between the armature commutator and carbon brush due to erosion. This interferes with the electric current flow, resulting in minimum or no power generation in the machine. In such a situation, you need to remove the eroded carbon brush and replace it with a new one.

Look For Sparks Coming Out Of Your Machines

If your tool or machine is malfunctioning, it might produce sparks when using it. Sparks are usually created when a tool’s air vent is blocked. This leads to overheating because there isn’t enough air circulation, which causes the generation of sparks.

Sparks from carbon brushes are generated when the carbon brush wears out, and its specks are deposited on the carbon brush channel. These specks block the air vent leading to spark generation. Therefore, if you notice sparks from your machine, you should take it as a sign you need to replace the worn-out carbon brushes.

Smell The Air Coming From Your Machines

A burning smell is another sign you can use to check whether you need to replace carbon brushes. At times, machines produce a burning smell when they’re used for a long period of time. If you notice a burning smell, you can shut down your machines for a while to allow their parts to rest and cool off.

If the burning smell persists, you should consider checking the condition of the carbon brushes.

Occasionally, a burning smell is produced due to friction of various parts, including carbon brushes. Friction causes damage to carbon brushes. Therefore, if there’s a burning smell, it may be time to replace the carbon brushes.

Look For Any Discoloration

You don’t have to wait until your machines start malfunctioning for you to inspect them. Instead, you can check them once in a while to be sure whether they’re okay or not. When checking them, you can look for discoloration signs. Discoloration of carbon brushes is an indication of overheating.

On the other hand, overheating is a sign that something in the carbon brush or machine isn’t working as it should. As mentioned above, overheating is sometimes caused by the accumulation of carbon brush specks on the air vent, interfering with air circulation. Therefore, if you notice that your machines’ carbon brushes are discolored, you need to replace them.

Be On The Lookout For Any Strange Sounds

Most machines produce sounds when they’re in use. However, there are times they can make strange sounds. These sounds are produced when some parts aren’t functioning correctly. For instance, a banging sound is heard when there’s a problem with carbon brushes.

When a carbon brush is severely damaged, it bounces off the commutator. As a result, it may end up hitting any other motor part. This leads to a banging sound that’s different from the sound made by a motor when there’s no issue. Therefore, if you hear a banging sound from a motor, you should first check if the carbon brush is intact. If it’s not, consider replacing it. Sometimes, the damage may be extreme to the point you have to replace the whole motor.

How To Maintain Carbon Brushes

You might be wondering what you can do to reduce the chances of replacing carbon brushes or how to maintain them after replacement. The following are some ways that can be of help:

- Often check whether commutators have slugs, fins, or mica

- Confirm whether carbon brushes can move freely in their holders

- Ensure the springs have the right amount of pressure

- Ensure the bearings are vibrating as they should. At times, they can vibrate excessively

- Make certain that the risers are well connected

- Ensure there’s no dirt accumulation on the carbon brushes

- Check whether there’s bar-to-bar deviation or roundness in the commutators

Use the most appropriate solutions if you notice any issues with the above procedures. It’s critical to ensure that carbon brushes are in good condition because motors can’t function without them. Cleaning your motor regularly is one of the solutions you can use to avoid the recurrence of such problems. What’s more, you can consult an expert.

Summing It Up

It’s normal for machines to malfunction. Malfunctions are mostly experienced when a machine’s parts are damaged or overused. A malfunction might result in you replacing some parts or buying another tool. However, you may purchase new tools or machines due to extreme damage if you don’t deal with malfunctions as soon as possible. One of the parts that can be replaced during a malfunction is a carbon brush.

A carbon brush is essential in the functioning of a motor. A machine’s motor can’t function without it. Therefore, if carbon brushes aren’t performing well or are damaged, you need to check whether they need replacement. If you’re unfamiliar with motors, you can use the information in this article when checking whether carbon brushes need replacement. All the best!

Leave a Reply