Logging of hole casing is a crucial part of the well-logging process. It lets you know about the mechanical state of the completed string.

It can track- down various mechanical problems that can affect the production or injection in the hole. It provides accurate details about the corrosion levels in the closed string. It is also beneficial in finding the erosion and geothermal deformation of the cased hole.

However, you have to use specific tooling for these logs. Here are the tools that are a must for this purpose.

Cased-hole calipers

This tool is beneficial in finding the changes in the diameter of the casing. It monitors the deformation that in turn indicated the total wear and corrosion of the hole. This tool is available with spring-powered feelers or fingers and measures casing sizes from 4 to 20inch in diameter.

The fingers on this tool are capable of recording one by thousands of an inch, radial resolution and approximately one by hundredth-inch, vertical resolution. Moreover, it takes readings, after every few seconds to ensure precise readings. Its fingers are also capable of retraction if the casing has a scale or collision.

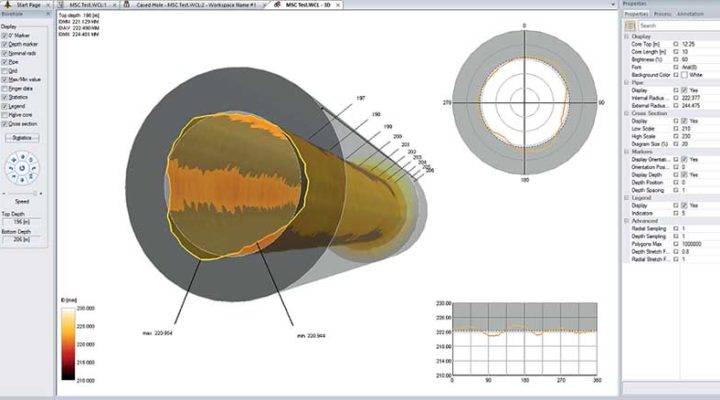

Most of the professional who provides cased hole well services use the modern version of this tool. This version has a low-pressure finger that doesn’t damage the casing and can indicate the pointer that is on the highest side of the well. Moreover, it can collect data that is enough to create a 3D picture of the casing. This image shows the housing along with its deformed and damaged parts.

Flux leakage tools

This semi-quantitative tool is used for analyzing the overall casing with its magnetic field.

The tools consist of spring-loaded, coil type and pad-mounted sensors that are pressed against the casing during the logging process. When there is corrosion or damage in the hole, the magnetic flux of this tool bulge out and a primary sensor measure this leakage to find induced voltage.

The sensor further uses this voltage reading to determine the volume and shape of the damage. The new tools are also using an additional eddy-current measurement system that helps to distinguish between internal and external losses.

Electromagnetic phase-shift tool

This tool uses the principle of electric phasing to find the damaged area with a resolution of approximately 1 foot. The device consists of a transmitting coil that generates a low-frequency magnetic field. It also induces an eddy current which in-turn create another magnetic field with the capability to phase-shift.

These fields are related to the thickness, conductivity and magnetic features of the casing and, this relation help to find the casing thickness.

This method is perfect for finding large corrosion areas and gradual thinning of the casing over time. The new version of the tool comes with multiple sensors that are more precise and allow electromagnetic variation. Moreover, the casing hole well services prefer this tool because it does not need proximity, so, it can examine a wide range of casing sizes.

Ultrasonic tools

Ultrasonic tools are an excellent choice if you need a full quantitative analysis of the bore. It has transducers which generate the ultrasonic pulse for imaging of the hole. The transmitted pulses get reflected after a while and this time difference between transmission and receiving help to find the casing thickness.

The latest tools use a rotating sensor with a very high frequency for more resolution and precise results. Moreover, the logging speed this tool is 425ft/hr and that too with a vertical resolution of 0.2-inch.

Summary

When you are dealing with a million-dollar business like oil mining safety and precautions are a must. While worker safety is assured through the right safety equipment, hole safety needs these tools.

They can help you determine and eliminate problems before it grows to a severe stage. Moreover, they also save the surrounding area from pollution and other hazards.

Leave a Reply